Trenchless Sewer Relining

Before trenchless pipe lining was offered, sewer pipe repairs were a big job for many homeowners. Large machinery and extensive labor crews had to excavate landscaping and driveways to just to access the pipes. This old approach involved costly repairs beyond the work of replacing the pipe like repaving sidewalks, driveways, roads and landscaping.

The old approach of digging up is still a viable option and sometimes needs to be done if the pipe is collapsed or too far gone to be relined. Thankfully, these days, the old way of doing things has been superseded by this new technology.

Our Plugged Pipes team is trained to offer this new service with accuracy and precision.

What is Trenchless Pipe Lining?

Trenchless pipe relining has been around for years, but the older technology involved complicated short windows to get the liner in place and hours to wait for it to cure in place.

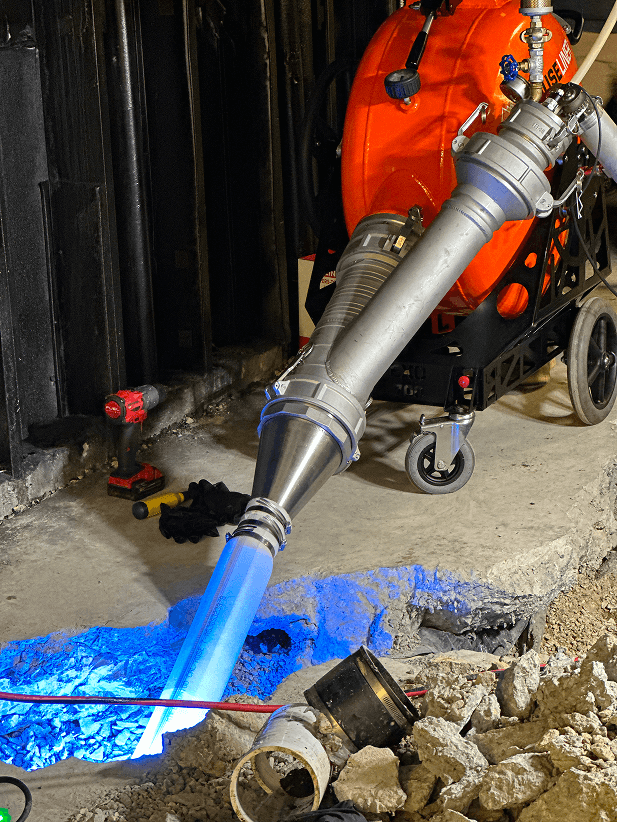

The new procedure is called cured-in-place pipe (CIPP) lining. It relines your sewer pipe from within, offering an excavation-free, underground solution for 3- 6 inch sewer pipes.

This minimally invasive, environmentally friendly process restores your pipe in less than a day using Blue Light Technology, preserving your yard while saving you time and money.

How the Trenchless Pipe Lining Process Works

Let’s go over what to expect when deciding on the trenchless relining for your sewer pipes.

- Sewer Camera Inspection

On site, our sewer lining process starts with a free sewer camera inspection. A sewer camera is inserted into the pipeline through an existing entry point, such as a drain or sewer cleanout.

The camera records the pipe’s interior from the building to the municipal connection in the road. This allows the technician to determine if this new service is an option and to locate cracks and determine if cleaning is needed before applying the liner. We will then get you a quote and get your job scheduled.

- Cleaning and Taking Measurements

If sewer lining is your decision, the next step is that the pipe must be cleaned for the lining to succeed. We use a descaling machine with carbide blades and hydro jetting, a high-pressure water flush, to remove corrosion and waste, leaving a smooth interior for the epoxy resin lining to adhere to and cure.

Next, we take the pipes’ measurements to know how much mixture and pipe liner to use. The resin is then measured and mixed according to these measurements.

- Resin Pouring, Inverting, and Curing

Our team pours the resin mixture into a felt tube coated with specialty epoxy resin and an inflation bladder, thoroughly saturating the liner. The resin-saturated liner is then inverted so the resin is on the outside, ready to adhere to the damaged pipeline. This inverted tube is inserted into the pipe using air pressure.

The tube is left inflated to allow the resin to cure and harden. Using Blue light curing technologies, we ensure the epoxy liner hardens in place, resulting in a strong, durable, and corrosion-resistant pipe.

Once cured, the tube and inflation bladder are removed, leaving a smooth new pipe resistant to corrosion and tree roots — all without extensive digging!

- Benefits of Installing Trenchless Sewer Pipe Lining

- Most cost effective way to replace your pipe

- Little or no digging required — no disturbance to landscaping, sidewalks, and driveways Minimal interruption to your daily routine

- Long-lasting economical solution

- Increased resale value when selling your home